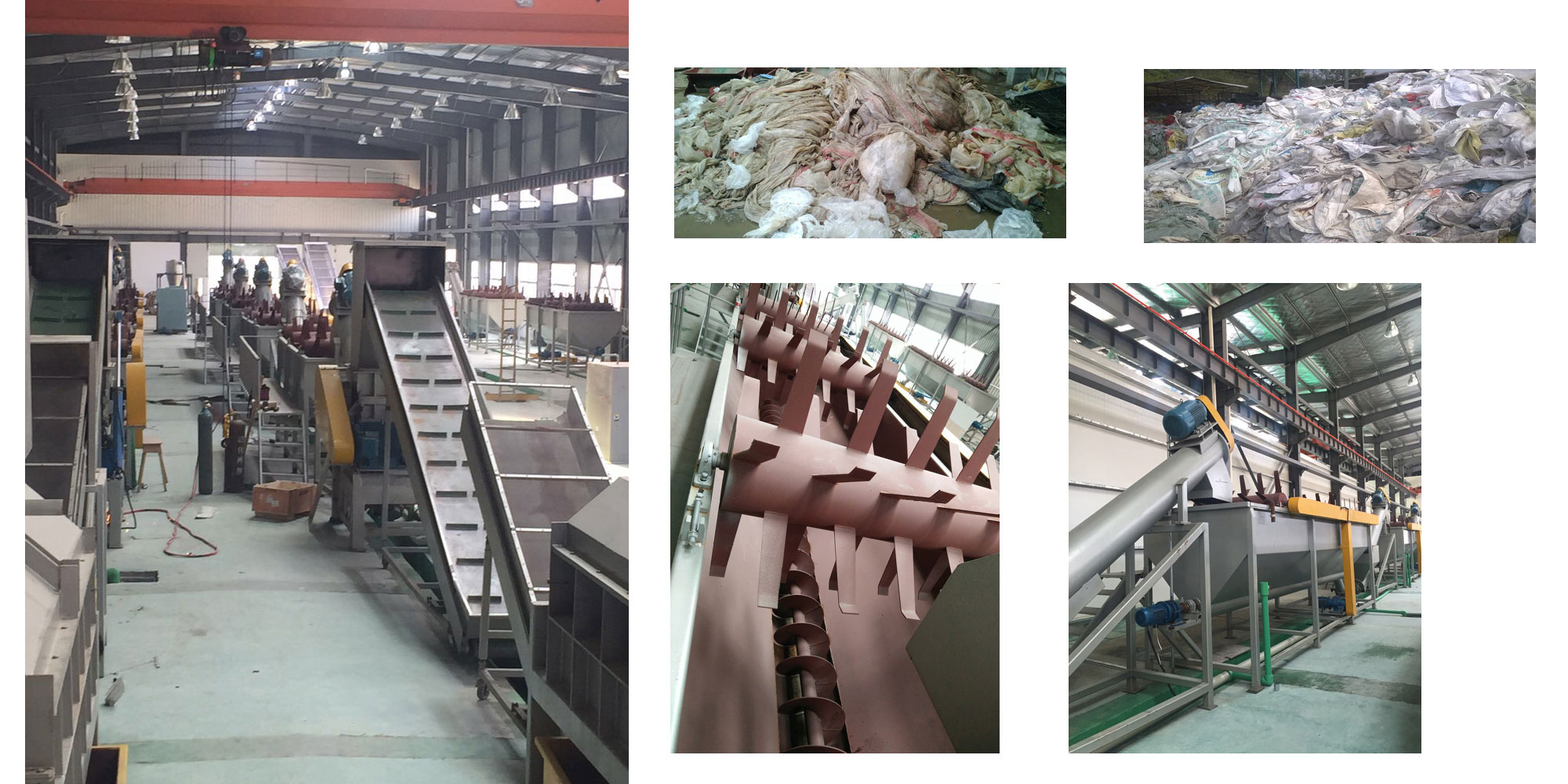

LLDPE waste film recycling production line, LDPE plastic sheeting recycling crushing washing line, recycling of waste LDPE film crushing equipment, cleaning and drying vinyl plastic film made particle recycling machinery, scrap film processing equipment, film recycling machine, LDPE film recycling line crushing granulation. Dispose of braided belt, film and other soft plastic floating class.Its capacity is from 300kg/h-2000kg/h.

Machine material is made from stainless steel 304 or Carbon steel.

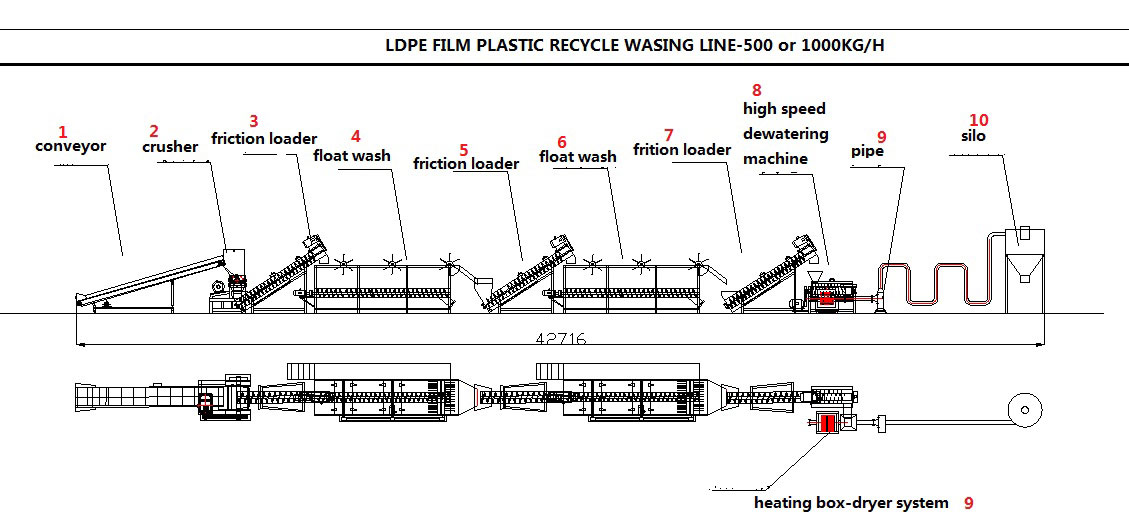

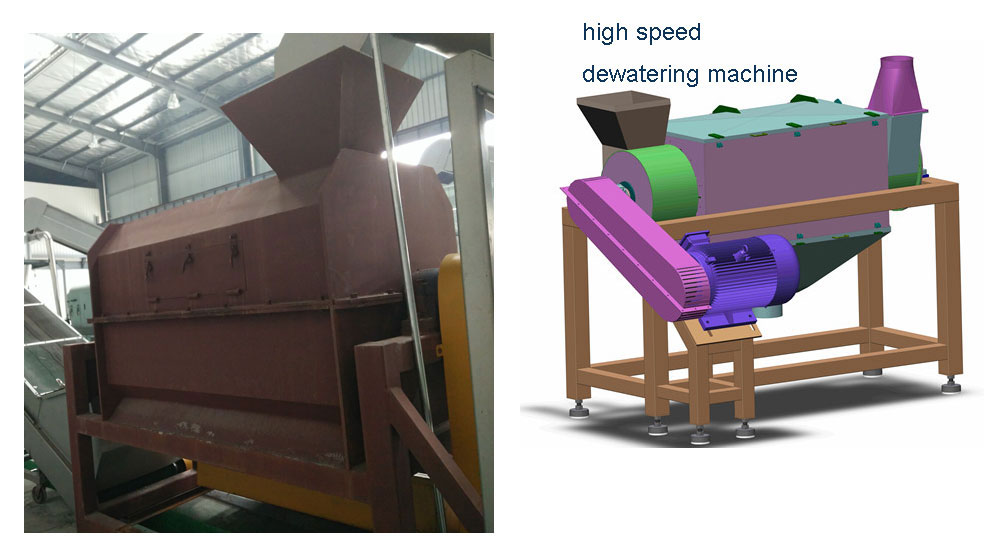

Its main process is conveyor to crusher(crushing) to friction loader(washing) to floating wash (washing)- to friction loader(washing) to floating wash(washing) – to friction loader(washing) to high speed dewatering machine(dehydration) to dryer system(drying) finally to silo(storing and packing)Plastic film is valuable secondary resources in recycling market, recycled film can be used to produce wide range of products.

The waste plastic film to be processed can be in different conditions in terms of humidity, contamination, form. The plastic film in recycling market are basically divided into the following families:

- Agricultural film (including greenhouse, mulching,, tunnel and banana film)

- Post-consumer film (including film from landfills and selective collections)

- Post-commercial and post-industrial film (including material 100% stretch)