Date: 17th Jun, 2017

Plastic blow molding machine from silver python machinery

Plastic blow molding machine from silver python machinery refers to the production of the parison by extrusion, in which it is placed in the blow mold closed mold compressed gas inflation, cooling after the mold out of the product

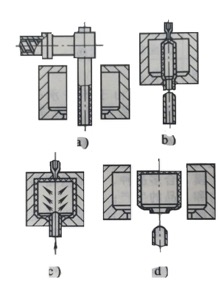

Plastic blow molding machine from silver python machinery process

1 extrusion parison

2 clamping and clamping the parison

3 inflated and cooled

4 open the mold out of the product

Plastic Blow molding Product type

1 packaging containers: bottles such as milk bottles, washing liquid bottles, oil bottles, etc .; barrels such as chemical reagent barrels, pure buckets and so on.

2 auto parts: engine piping, cooling pipes, exhaust pipes, bumper, fuel tank

3 daily necessities, toys, furniture, toolbox

Plastic Blow molding Advantage

1 mold and mushroom costs are low, because the blow molding used in the blow molding molds do not need to bear the higher pressure and temperature, mold materials in addition to the choice of carbon steel, you can also use aluminum, stainless steel and other processing , Reducing the cost.

2 products are relatively rich, can produce volume 1ML to 10000L containers, to 5ML-3000L hollow containers mostly

3 can produce large hollow products

4 can produce complex hollow products, with the development of hollow blow molding technology, has broad prospects for development

5 rapid development, hollow blow molding has become the first extrusion, injection molding products in the third after the plastic molding method

6 production efficiency and automation than other hollow forming method to be high

Disadvantages

1 products require hollow or tubular, the product shape has some restrictions

2 wall thickness is not easy to control, product wall thickness and parison thickness, material properties, compressed air pressure, cooling time and temperature and many other factors related to control a certain degree of difficulty.

3 compared with the injection molding products, blow molding products, low dimensional accuracy, but higher than other hollow molded products, high precision, in addition, the product surface roughness is high.